About us

Harder & Steenbeck

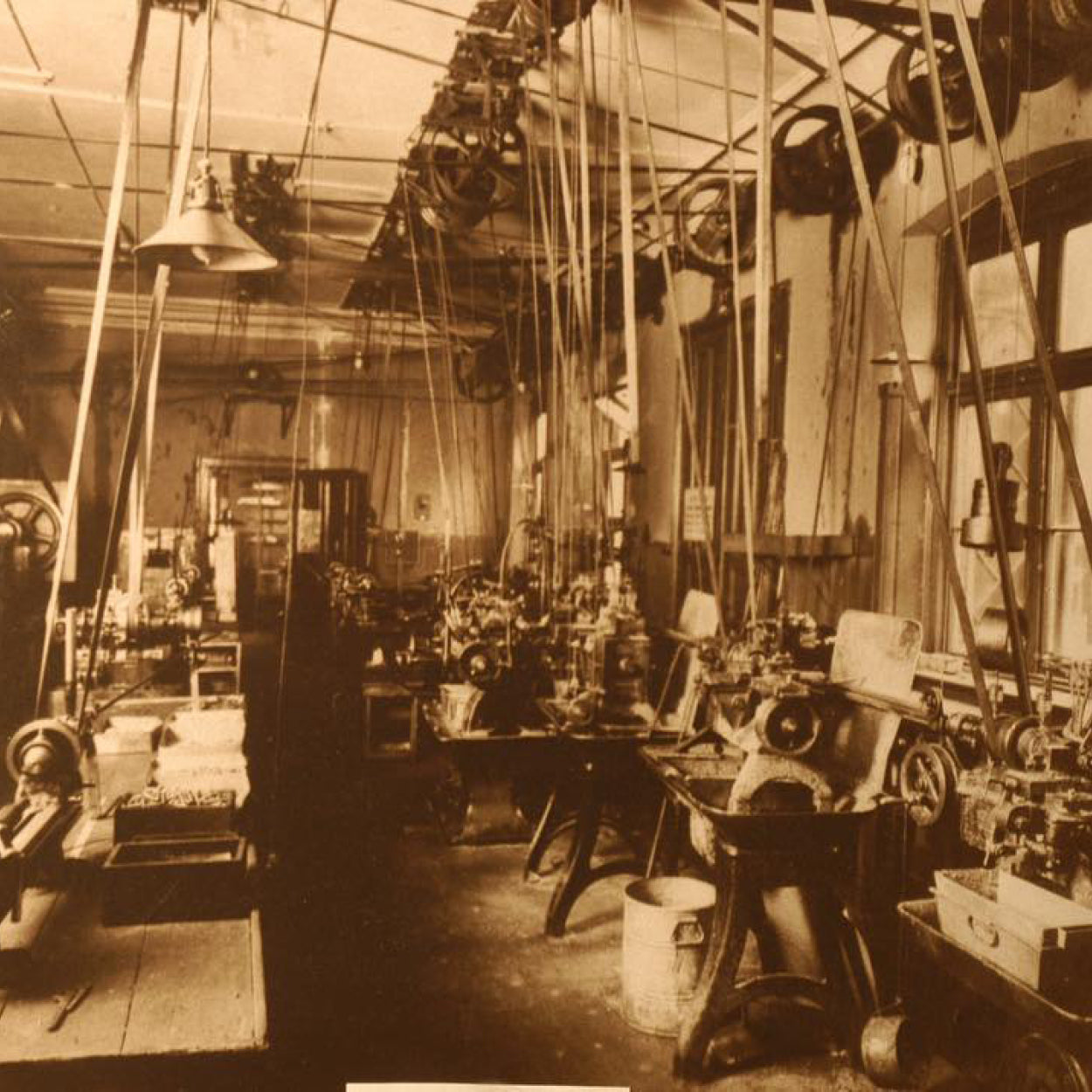

In 2013 Harder & Steenbeck celebrated the company’s 90th anniversary. The celebrations provided an opportunity to receive an in-depth look into the history of our corporation. Thorough research had revealed the ups and downs our business had gone through; changes closely linked to the world history. It shed light on people and products who shaped the company’s image. It was incredibly insightful and interesting to observe the leitmotiv, which had defined the company character of “Harder & Steenbeck” ever since its humble beginnings. We call it: “The joy of innovation”.

Mission Statement

Environmental Prodection

Harder & Steenbeck is committed to contributing to the protection of the environment and the climate. They use high-quality European raw materials and recycle surplus materials during the manufacturing of their airbrushes. Oil and grinding water from production are also recycled in an environmentally conscious manner.

All printed materials are produced in German companies that print in a carbon-neutral way, with CO2 emissions kept to a minimum and compensated for through recognized climate projects. They support established environmental protection projects and use recyclable paper from sustainable forest managements. They exclusively procure green electricity from natural sustainable sources in Northern Germany, avoiding the use of electricity generated by coal-fired and atomic power stations. Harder & Steenbeck's commitment to sustainability and environmental protection sets an excellent example for other companies to follow.

Mission Statement

Electronic Equipment

This information is for end users of electrical and electronic equipment and highlights the importance of environmentally-friendly disposal of old devices. The Waste of Electrical and Electronic Equipment (WEEE) should not be disposed of with residual waste, and owners must separate them from municipal waste and hand them in at collection points.

Owners must also separate old batteries and accumulators not built into the device. The symbol for separate collection of electrical and electronic equipment is a crossed-out wheeled bin. Old devices can be returned to collection points set up by public waste disposal authorities for proper recycling. Information on collection and return points can be found on the website https://www.ear-system.de/ear-verzeichnis/sammel-und-ruecknahmestellen. Information about EU-wide guidelines and national collection points can be found on the website of the European Environment Agency.

Mission Statement

Employee Philosophy

Hand in hand teamwork and social equality are very important to us. For that reason we currently employ 39 full-time employees, including two individuals with severe handicaps.

Our working premises, including all operational plant, machinery and equipment, are designed to facilitate the handicapped workers, so none of the staff members feels at disadvantage during work.

OUR TEAM

Our History

Albert Einstein

Creativity is intelligence having fun